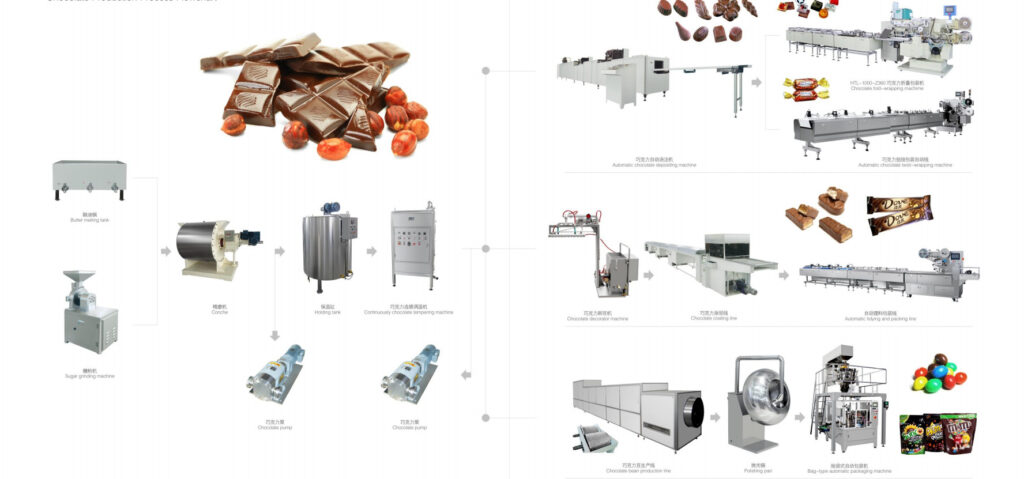

Chocolate production process flowchart

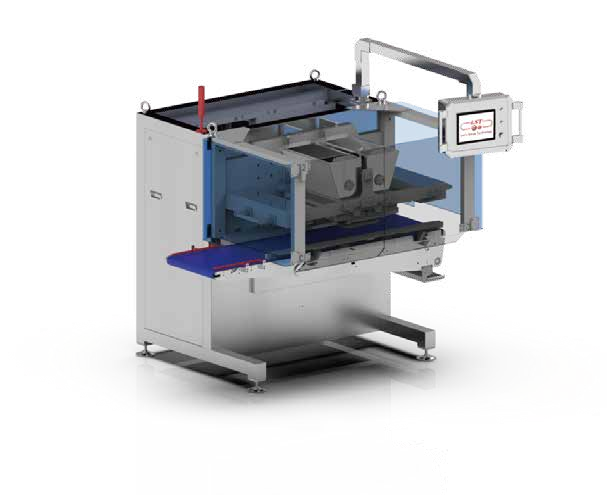

Explain For Chocolate Enrobing Machine

Chocolate Enrobing Machine is the dedicated equipment for making assorted chocolate products with functions of whole coating, single-sided coating, partial coating and cooling. It can enrobe chocolate pastes on many kinds of food, such as pastry, pie, biscuit, wafer, candy and etc. to form chocolate products with various unique flavors.

System Composition

| 1 | Conveying belt |

| 2 | Enrobing unit |

| 3 | Controlling cabinet |

| 4 | Chocolate warm keep and circulating system |

| 5 | Cooling tunnel |

| 6 | Refrigeration unit |

| 7 | Frame |

| 8 | Accessories |

| 9 | Material sprinkler with elevator |

| 10 | Chocolate decorate machine |

Chocolate Decorate

After the product enrobing the chocolate liquid, here the decorate machine before the cooling tunnel, decorate different texture above the chocolate, appearance look great.

Sprinkler And Elevating Machine

After the product enrobing the chocolate liquid, here the sprinker before the cooling tunnel,spraying the material above the product, such like season and broken nuts or elase client want to add, to enhance the taste of chocolate product.

Machine Advantages

1-Material hopper underneath the enrobing head is able to be pulled out for cleaning;

2-Enrobing head delivery belt, cooling tunnel belt, the chocolate pastes delivery pump as well as the pastes blowing fan are all with frequency control;

3-Material hopper on the upper part of the enrobing head for chocolate pastes supplying is able to be moved forward and backward;

4-For avoiding material overflow, there are liquid level controllers installed on the material hoppers;

5-Food grade PU conveyor belt has photoelectric automatic correction (the compressed air for the pneumatic air cylinders for automatic correction should be prepared by clients).

6-The stainless steel boards for supporting the PU belt are able to be pulled out for cleaning.

7-The cooling tunnel covers are with opening lids.

8-Machine material: SUS304 enrobing head, pipes, pump, cooling tunnel frame, machine covers and cooling tunnel covers. The covers used as insulation purpose have high-density foam in the middle of the SUS304 bended covers.

9-Fully welding, washable.

| Item/Model | YZ-400 | YZ-600 | YZ-800 | YZ-1000 | YZ-1200 |

| Wiremesh and belt width (mm) | 400 | 600 | 800 | 1000 | 1200 |

| Wiremesh and belt speed (n/min) | 1-6m | 1-6m | 1-6m | 1-6m | 1-6m |

| Refrigeration Unit | 2 | 2 | 2 | 3 | 3 |

| Cooling tunnel length (m) | 10 | 14 | 18 | 22 | 26 |

| Total Power (Kw) | 10 | 16.5 | 20 | 28.5 | 32 |

| Weight (Kg) | 1800 | 2300 | 3200 | 4050 | 4600 |

| Dimension (mm) | 13160*700*1500 | 17500*950*1800 | 21500*1100*1800 | 25500*1250*1800 | 29500*1400*1800 |

Related Products

FAQ

Q:Are you a factory or trading company ?

A:We are a factory specializing in manufacturing, R&D, and have our own foreign trade rights and production equipment.

Q:Could you please send me your best price?

A:Yes, we cherish every cooperative customer and work hard to facilitate transactions.

And before quoting,please kindly consult us and provide:

1)The type of packing your product.

2)Your product's size, and your expected speed for machine.

So that we can recommend the most corresponding machine.

Q:When is your delivery time ?

A:Single machine:30-45 working days.Production line:60-75 working days after 30%-50% deposit received.

Q:When is your payment term ?

A:Payment shall be 30%-50% deposit by T/T,balance 50%-70% paid by T/T,D/P after inspection but before shipment.

Q:Can you make machines based on customer's design ?

A:Yes,we can customized. According to your special request,we can design solution and provide service scheme.

Q:How to handle the installation and test for machine?

A:Our engineers are available to service overseas to install and train local staff.Specific arrangements will be explained clearly in each quotation.

After-sales Service

Technical Support

1.Customised machine;

2.Customized layout drawings;

3.Commissioning and installation before delivery;

4.Overseas engineers to install and debug ,Training ;

5.Formula debugging;

6.Upgrading and transformation, make your equipment back to a better state and solve the problem of insufficient output;

7.24-hour online technical support and service.

Spare Parts Service

1.A processing centre for Perishable parts, sent abroad in a second.

2.During the warranty period, we can provide replacement parts free of charge, except in the case of artificially damaged parts.

Maintenance

The seller guarantees the quality of the products for 12 months since the date of installation. During the warranty period, any problems/defaults happen on the hard parts of the machinery, the buyer will replace the parts at the seller's cost (Free). If the defaults are aroused by the defaulted operations, or the buyer needs the technical assistance for the processing problems, the buyer should be responsible for all the cost and their allowance.

Packaging And Shipping

Usually shipping by sea, Packed in wooden crates, wooden pallets.

And before we pack, we will apply protective oil on the machine to reduce the contact between the machine and the air.

About Our Company--Yingzoom

Shanghai Yingzoom Industrial Co., Ltd. is a professional manufacturer of candy machine, biscuit machine and other food machine, supplying high-quality candy production line.

And we are also a professional labeling machine manufacturer, focusing on the research and development of candy machinery and labeling machines,Sales and formulate professional solutions for special industries.