Technical Parameters

|

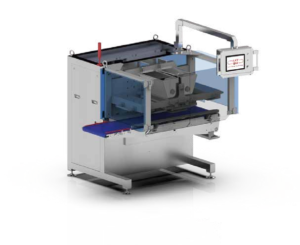

Name | YZ-C120 ONE-SHOT CHOCOLATE DEPOSITOR |

| Heating | Separated heating for hoppers and valves |

| Pot Capacity | 8L*2 |

| Drive Motor | All movements are activated by 4 sets of 0.4kw servo motors |

| PLC | Standard DELTA PLC, Siemens PLC available |

| Power | 110/220V-single phase 50/60HZ, or customized |

| Machine Size | 115*67*144cm |

| Machine Weight | 346kg |

| Package Size | 129*79*167cm |

Package Weight | 394kg |

Characteristic

The One Shot Depositor is capable of depositing chocolate with varying thicknesses and consistencies directly into polycarbonate molds or trays. With One Shot technology, this machine can produce up to 60-120 kg of chocolates per hour, including pra lines,chocolate bars, bonbons, center filled chocolates, etc. It is designed specifically to help optimize small to medium production processes.

Product Information

Holding Tank

The chocolate holding tank or chocolate storage tank is used for holding the fine grinded chocolate paste.This chocolate tank has functions of temperature decrease, increase and preservation. Besides, it also can preventfat separation.

Plastic Molds

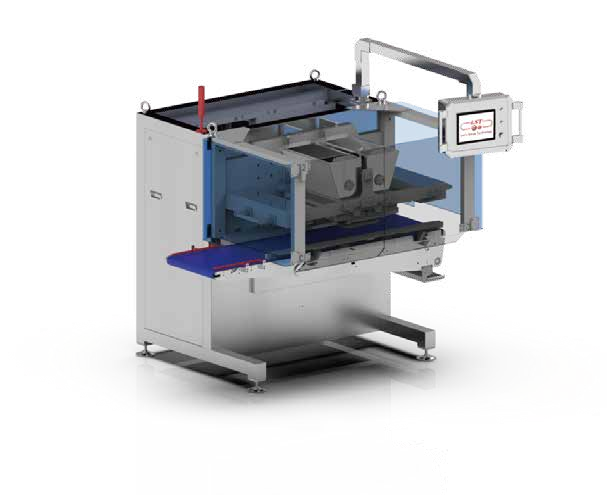

YZ-C 120 MINI ONE-SHOT DEPOSITING LINE

| Out Put | 4-8molds/minute, depending on product size and structure |

| Mould Size | 275×175mm/275×135mm |

| PLC/Touch Screen | DELTA |

| Power | 220V/380V, or customized |

Characteristic

We combine the molding machine with other related equipment to form a standard fully automated production line. This production line utilizes a modular system which allows for the addition of related equipment to produce various types of products according to needs. We also offer customized molding solutions to cater to specific customer needs, helping to improve your production efficiency and product quality.

Related Products

FAQ

Q:Are you a factory or trading company ?

A:We are a factory specializing in manufacturing, R&D, and have our own foreign trade rights and production equipment.

Q:Could you please send me your best price?

A:Yes, we cherish every cooperative customer and work hard to facilitate transactions.

And before quoting,please kindly consult us and provide:

1)The type of your product.

2)Your product's size, and how much capacity do you need.

So that we can recommend the most corresponding machine.

Q:When is your delivery time ?

A:Single machine:30-45 working days.Production line:60-75 working days after 30%-50% deposit received.

Q:When is your payment term ?

A:Payment shall be 30%-50% deposit by T/T,balance 50%-70% paid by T/T,D/P after inspection but before shipment.

Q:Can you make machines based on customer's design ?

A:Yes,we can customized. According to your special request,we can design solution and provide service scheme.

Q:How to handle the installation and test for machine?

A:Our engineers are available to service overseas to install and train local staff.Specific arrangements will be explained clearly in each quotation.

After-sales Service

Technical Support

1.Customised machine;

2.Customized layout drawings;

3.Commissioning and installation before delivery;

4.Overseas engineers to install and debug ,Training ;

5.Formula debugging;

6.Upgrading and transformation, make your equipment back to a better state and solve the problem of insufficient output;

7.24-hour online technical support and service.

Spare Parts Service

1.A processing centre for Perishable parts, sent abroad in a second.

2.During the warranty period, we can provide replacement parts free of charge, except in the case of artificially damaged parts.

Maintenance

The seller guarantees the quality of the products for 12 months since the date of installation. During the warranty period, any problems/defaults happen on the hard parts of the machinery, the buyer will replace the parts at the seller's cost (Free). If the defaults are aroused by the defaulted operations, or the buyer needs the technical assistance for the processing problems, the buyer should be responsible for all the cost and their allowance.

Packaging And Shipping

Usually shipping by sea, Packed in wooden crates, wooden pallets.

And before we pack, we will apply protective oil on the machine to reduce the contact between the machine and the air.

About Our Company--Yingzoom

Shanghai Yingzoom Industrial Co., Ltd. is a professional manufacturer of candy machine, biscuit machine and other food machine, supplying high-quality candy production line.

And we are also a professional labeling machine manufacturer, focusing on the research and development of candy machinery and labeling machines,Sales and formulate professional solutions for special industries.