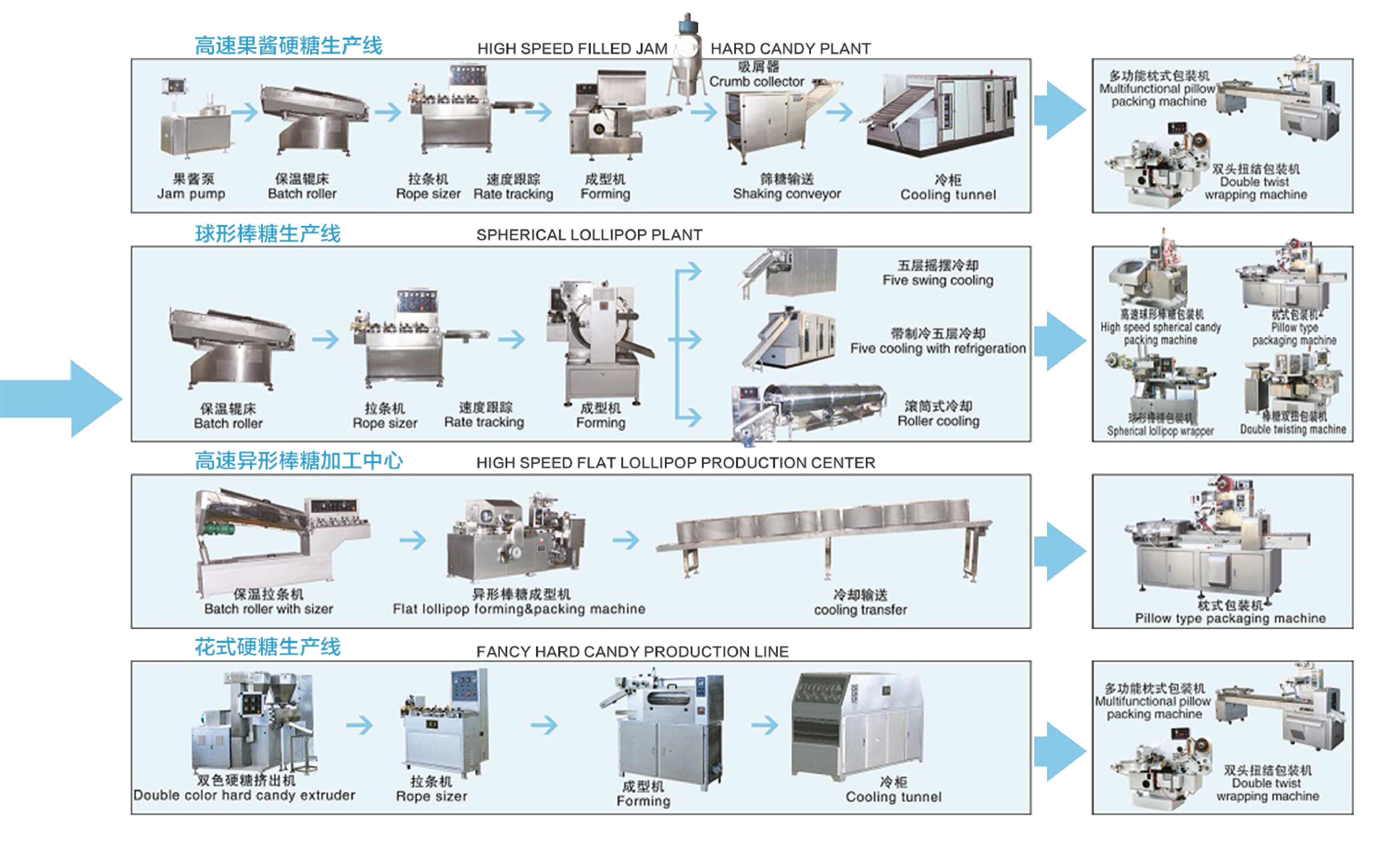

Hard Candy/Lollipop Production Line

The full automatic candy machine can make hard candy, lollipop, etc. The weight range of the candy is 1-10g. If you need a larger candy, we can customize it. Re-design the candy machine according to customer requirements to meet customer requirements.

The machine has almost no wearing parts, and it can be used for 5- 10 years or even longer under the premise of non-human damage.

Technical Parameters

| Name | Capacity(kg/h) | Power(kw) | Dimension(mm) |

| Batch Roller With Sizer | / | 7.15 | 3200x560x1700 |

| Molding Machine | 3-8 ton/day | 3.38 | 1400x910x1450 |

| Cooling Conveyor | / | 2.81 | 5200x1500x2120 |

| Double-punch high speed forming machine for lollipop | 1800pcs/min | 4.78 | 1550x1260x1450 |

Characteristic

1.The speed is controlled by frequency conversion to ensure coordination across the entire line.

2.The forming mold is a pressure plate type to ensure that the sugar granules are fully formed and the rods are inserted accurately.

3.Swing cooling conveyor keeps the sugar cubes from deforming during the conveyance process.

4.Molding speed automatic tracking.

Types Of Candy (Shapes can be customized)

Product Informations

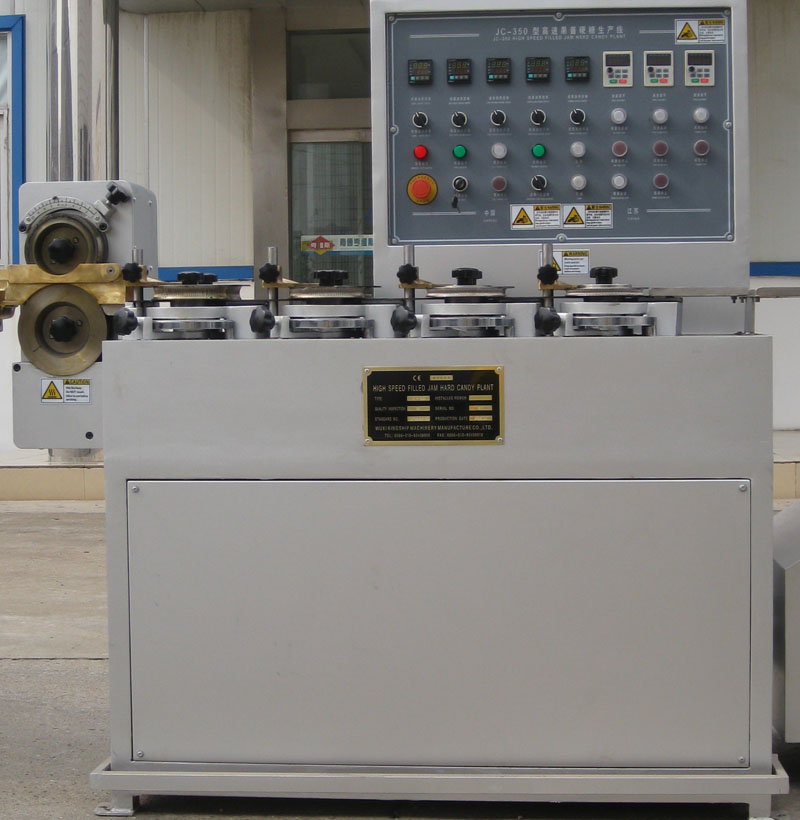

1.Batch Roller

The machine has four tapered rollers in order to make sugar paste keep a suitable temperature to prevent stiffen and form roller to facilitate to pull, and if adding ancillary equipments it will enable to infuse dry small particles, silty and viscous liquid substances into rolling massecuite through continuous rolling. This machine has many features: safe, easy to operate and adjust, the labor intensity is reduced, and the production efficiency is improved. It is indispensable major equipment before continuously producing and forming.

2.Rope Sizer

Because the candy output from the batch roller is thicker, the candy should be gradually fine-drew evenly pulled by the rope sizer. This machine has many features: safe, reliable, easy to operate and adjust, the labor intensity is reduced, and the production efficiency is improved. It is indispensable major equipment before continuously producing and forming. This machine consists of disk components, mechanical drive components, electric heating and heat preservation device, and frame components.

3.Molding Machine

This machine is suitable for making different shapes of lollipop candies. It is the essential forming equipment for making die-formed lollipop. This machine features producing candies with consistent shapes and weight. This compact machine also makes less sprinkles and noises.

Candy shape: Spherical, oblate, ellipsoidal and many other irregular shapes.

4.Cooling Tunnel/Machine

The cooling machine can be connected to every kind of forming machines. It has a wide range of applicant. According to different requirement, it can be made in many specifications. It has good effect on cooling the candy and the candy will not be easy to deform and craze. During cooling, it also can screen out every kind of oddments which produce during production process. After cooling, the candy is consistency, has beautiful shape and no waste.

Related Products

FAQ

Q:Are you a factory or trading company ?

A:We are a factory specializing in manufacturing, R&D, and have our own foreign trade rights and production equipment.

Q:Could you please send me your best price?

A:Yes, we cherish every cooperative customer and work hard to facilitate transactions.

And before quoting,please kindly consult us and provide:

1)The type of hard candies/lollipop you produce.

2)Your product's size, and your expected capacity for machine.

So that we can recommend the most corresponding machine.

Q:When is your delivery time ?

A:Single machine:30-45 working days.Production line:60-75 working days after 30%-50% deposit received.

Q:When is your payment term ?

A:Payment shall be 30%-50% deposit by T/T,balance 50%-70% paid by T/T,D/P after inspection but before shipment.

Q:Can you make machines based on customer's design ?

A:Yes,we can customized. According to your special request,we can design solution and provide service scheme.

Q:How to handle the installation and test for machine?

A:Our engineers are available to service overseas to install and train local staff.Specific arrangements will be explained clearly in each quotation.

After-sales Service

Technical Support

1.Customised machine;

2.Customized layout drawings;

3.Commissioning and installation before delivery;

4.Overseas engineers to install and debug ,Training ;

5.Formula debugging;

6.Upgrading and transformation, make your equipment back to a better state and solve the problem of insufficient output;

7.24-hour online technical support and service.

Spare Parts Service

1.A processing centre for Perishable parts, sent abroad in a second.

2.During the warranty period, we can provide replacement parts free of charge, except in the case of artificially damaged parts.

Maintenance

The seller guarantees the quality of the products for 12 months since the date of installation. During the warranty period, any problems/defaults happen on the hard parts of the machinery, the buyer will replace the parts at the seller's cost (Free). If the defaults are aroused by the defaulted operations, or the buyer needs the technical assistance for the processing problems, the buyer should be responsible for all the cost and their allowance.

Packing and Shipping

Usually shipping by sea, Packed in wooden crates, wooden pallets.

And before we pack, we will apply protective oil on the machine to reduce the contact between the machine and the air.

About Our Company--Yingzoom

Shanghai Yingzoom Industrial Co., Ltd. is a professional manufacturer of candy machine, biscuit machine and other food machine, supplying high-quality candy production line.

And we are also a professional labeling machine manufacturer, focusing on the research and development of candy machinery and labeling machines,Sales and formulate professional solutions for special industries.