Gummy candy production line

The full automatic candy machine can make soft candy, hard candy, lollipop, etc.

The weight range of the candy is 1-10g. If you need a larger candy, we can customize it. Redesign the candy machine according to customer requirements to meet customer requirements.

The depositing machine is assisted by PCL control panel, which is convenient to operate, and the number and speed of depositing, hopper temperature, etc.

The candy machine is simple to clean after use, and the cleaning steps can be completed by depositing heated water several times.

The machine has almost no wearing parts, and it can be used for 5- 10 years or even longer under the premise of non-human damage.

Technical Parameters

| Name | Cooker System (Cooker+Pump + Storage Tank) | YZ-150 Automatic Candy Line |

| Voltage | 380V | AC 380V 50/60HZ 3PH |

| Power | 22KW | 12kw |

| Depsiting Speed | / | 45 times/min |

| Capacity | 200L/300L | 150kg/h |

| Servo Brand | / | DELTA |

| Temperature Sensor | / | Omran |

| Applicable Depositng Amount | / | 1-10g |

| Weight | 600KG | About 3500kg |

Details Pictures

Characteristic

1.Servo depositing. Servo control system produces consistent shape and piece weight as well as precisely controlled dosing of active ingredients.Products have a high-quality appearance and long shelf life.

2.The depositing speed can reach 45 times/min. It is easy to operate, clean, and replace. More advantages than other manufacturers.

3.Using internationally renowned servo motors, precise depositing volume, chain drive, quick disassembly and replacement, and better stability.

4. All made of SUS 304 stainless steel.

5.Siemens touch screen control page is more convenient and easy to operate.

6.The hopper can be replaced quickly,which is convenient for cleaning and replacement

7.With automated conveying chain,will be more convenient to deposited and control.

8.With cooling tunnel.

Types Of Candy (Shapes can be customized)

Product Information

1.Cooker system

Cooker, by Heating Method:

1. Electric cooking: heating with heat conduction oil, the temperature range is 70-210°C;

2. Steam cooking: steam heating, the temperature range is 70-280℃;

3. Electromagnetic cooking: electromagnetic heating, maximum temperature 300°C.

According to the structure form:

1. Tiltablesandwichcooker, the tiltable sandwich cooker can be tilted up to 90°, and the tilting method is manual flipping.

2.Vertical(fixed) sandwichcooker.

Divided by process:

with or without stirring.

Q1: What should I chose for mine cookers by steam or electrical heating?

A:Depending on the customer's requirements,whether or not the steam system/quality/cost requirements,steam heating is usually faster.

For example,if the customer has a boiler,it is recommended that the customer use steam heating.

Q2: Does the mixer speed and high shearing speed can be adjust?

A:The high shearing is a fixed value,immutable;

The mixer speed is adjustable,usually a transmission or reducer is added.

Eg:The reducer used in high viscosity.

.png)

.png)

2.Different kinds of Mold

Q1: How many types of molds can be used on machine?

A:metal mold;silica gel mold;3D mold;

Metal molds are divided into quick release mold and planar mold .

Q2: How does the demoulding system working?

A:The tank chain is demoulded.

The nails push the candy down and brush candies by brush.

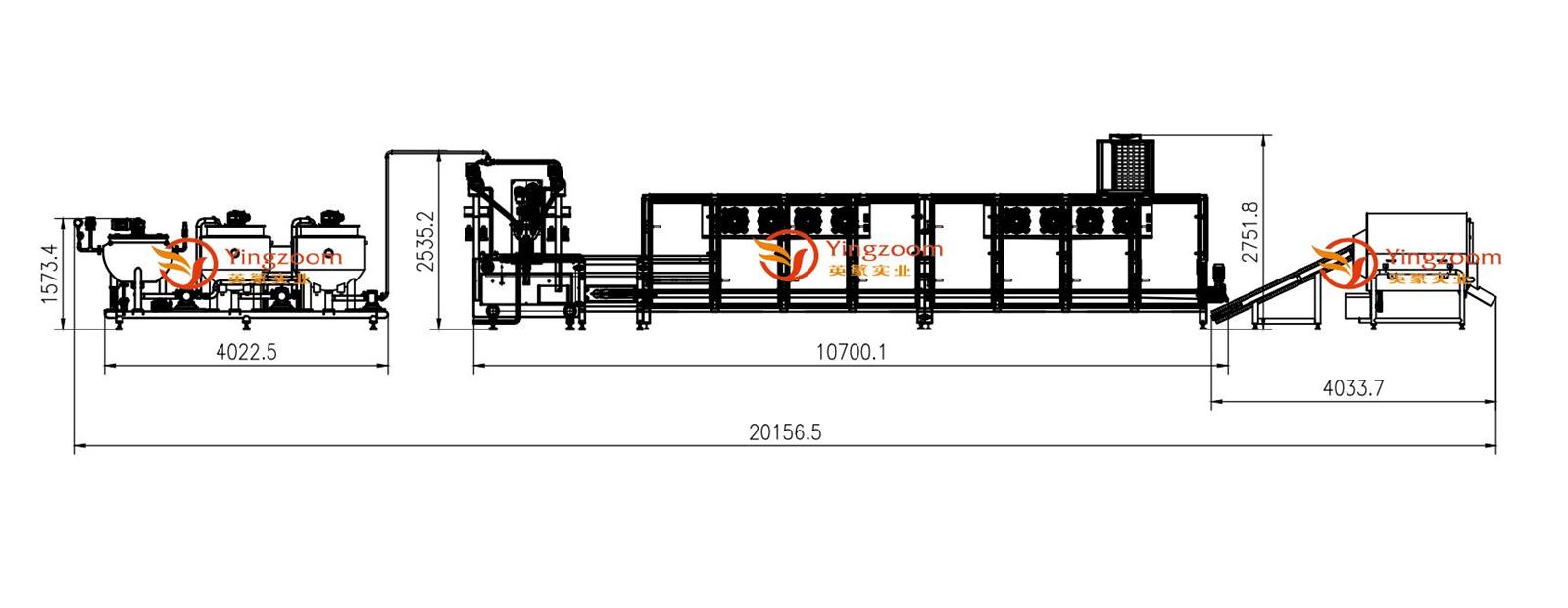

YZ-150 Full Automatic Gummy Candy Line Layout

Design and layout adjustments can be made according to the actual conditions of the customer's factory

Related Products

FAQ

Q:Are you a factory or trading company ?

A:We are a factory specializing in manufacturing, R&D, and have our own foreign trade rights and production equipment.

Q:Could you please send me your best price?

A:Yes, we cherish every cooperative customer and work hard to facilitate transactions.

And before quoting,please kindly consult us and provide:

1)The type of candies you produce.

2)Your product's size, and your expected capacity for machine.

So that we can recommend the most corresponding machine.

Q:When is your delivery time ?

A:Single machine:30-45 working days.Production line:60-75 working days after 30%-50% deposit received.

Q:When is your payment term ?

A:Payment shall be 30%-50% deposit by T/T,balance 50%-70% paid by T/T,D/P after inspection but before shipment.

Q:Can you make machines based on customer's design ?

A:Yes,we can customized. According to your special request,we can design solution and provide service scheme.

Q:How to handle the installation and test for machine?

A:Our engineers are available to service overseas to install and train local staff.Specific arrangements will be explained clearly in each quotation.

After-sales Service

Technical Support

1.Customised machine;

2.Customized layout drawings;

3.Commissioning and installation before delivery;

4.Overseas engineers to install and debug ,Training ;

5.Formula debugging;

6.Upgrading and transformation, make your equipment back to a better state and solve the problem of insufficient output;

7.24-hour online technical support and service.

Spare Parts Service

1.A processing centre for Perishable parts, sent abroad in a second.

2.During the warranty period, we can provide replacement parts free of charge, except in the case of artificially damaged parts.

Maintenance

The seller guarantees the quality of the products for 12 months since the date of installation. During the warranty period, any problems/defaults happen on the hard parts of the machinery, the buyer will replace the parts at the seller's cost (Free). If the defaults are aroused by the defaulted operations, or the buyer needs the technical assistance for the processing problems, the buyer should be responsible for all the cost and their allowance.

Packaging And Shipping

Usually shipping by sea, Packed in wooden crates, wooden pallets.

And before we pack, we will apply protective oil on the machine to reduce the contact between the machine and the air.

About Our Company--Yingzoom

Shanghai Yingzoom Industrial Co., Ltd. is a professional manufacturer of candy machine, biscuit machine and other food machine, supplying high-quality candy production line.

And we are also a professional labeling machine manufacturer, focusing on the research and development of candy machinery and labeling machines,Sales and formulate professional solutions for special industries.